The bottleneck in digitisation

Expand the table of contents

Digitalisation is high on the agenda at many companies. New tools, new platforms, new automation. The project lists are long and continue to grow every year. Meetings often involve fifteen projects being discussed at the same time: a new CRM, a workflow in purchasing, a dashboard for management, marketing automation and an AI agent system in sales. Everything sounds important. And because no one wants to lose sight of any of the issues, budget and attention are distributed according to the scattergun principle: everyone gets something, but no one gets enough.

The result is sobering. A lot is started, little is finished, and almost nothing has a noticeable effect. The figures back this up: according to McKinsey, around 70 per cent of digitalisation initiatives are considered to have failed or to be insufficiently effective. [1] In its 2025 study, Bitkom shows that more than half of companies are now struggling to cope with digitalisation at all. [2] The trend is increasing year on year.

The problem rarely lies in the technology and even less often in a lack of expertise. It is because energy is spread too thinly in too many directions. Optimising a little bit everywhere means achieving no real change anywhere. Companies work on many symptoms at the same time, but overlook the cause behind most problems.

This article addresses precisely that issue. It shows why companies do not fail because of fifteen equally important challenges, but because of a single limiting factor. Why an unrecognised bottleneck prevents more growth than any missing tool. And how you can identify, evaluate and specifically solve this bottleneck. Because only when it is clear what is really slowing down your company can digitalisation begin to have an impact.

The bottleneck that really slows down your digitalisation

When companies try to push ahead with many digitalisation initiatives in parallel, it often seems as if they are failing due to a multitude of equally challenging problems. But this is a fallacy. In practice, they usually fail not because of a lack of technology, skills or budget, but because of a single process that unnoticed slows down the entire system.

Eliyahu Goldrat’s theory of constraints clearly describes this principle. [3] A company’s throughput is determined by exactly one limiting factor. You can optimise and invest in many areas. As long as the bottleneck remains unchanged, the overall system will not change. A chain will always break at its weakest link. And that’s exactly how it is with your processes.

Two practical examples illustrate what this means in concrete terms:

A medium-sized mechanical engineering company with 180 employees distributed its digitalisation budget across several parallel projects. CRM, ERP, archiving, time recording, automation. A year later, none of these projects had been completed and morale within the company was low. Only a systematic analysis revealed what was actually slowing things down. It took an average of twelve days to prepare a quotation. Customers were leaving, the technical team was overloaded and around a third of all enquiries remained unprocessed. The solution was not to introduce more tools, but to focus. A quotation configurator with automated calculation was introduced. The result: quotation times fell from twelve to two days, qualified quotations rose by 45 per cent and turnover increased by 18 per cent. The bottleneck was identified and eliminated, and the remaining projects could later be realised with the additional revenue generated.

The second example shows how common such bottlenecks are. An e-commerce company wanted to invest simultaneously in social media automation, retargeting, AI-supported product descriptions and a new merchandise management system. But the real bottleneck lay elsewhere: returns processing was so time-consuming that the team could barely keep up. Each return took 45 minutes of manual work, and the return rate was 20 per cent. It was only the introduction of an automated returns process that brought about the turnaround. Processing time fell to eight minutes, costs dropped significantly and customer satisfaction rose noticeably.

These two cases highlight what remains invisible in many companies. Digitalisation rarely fails because of the number of projects. It fails because the one process that has the greatest impact on speed, quality and yield is not recognised. However, once this bottleneck is identified and specifically addressed, it creates a noticeable lever. This is exactly where effective digitalisation begins.

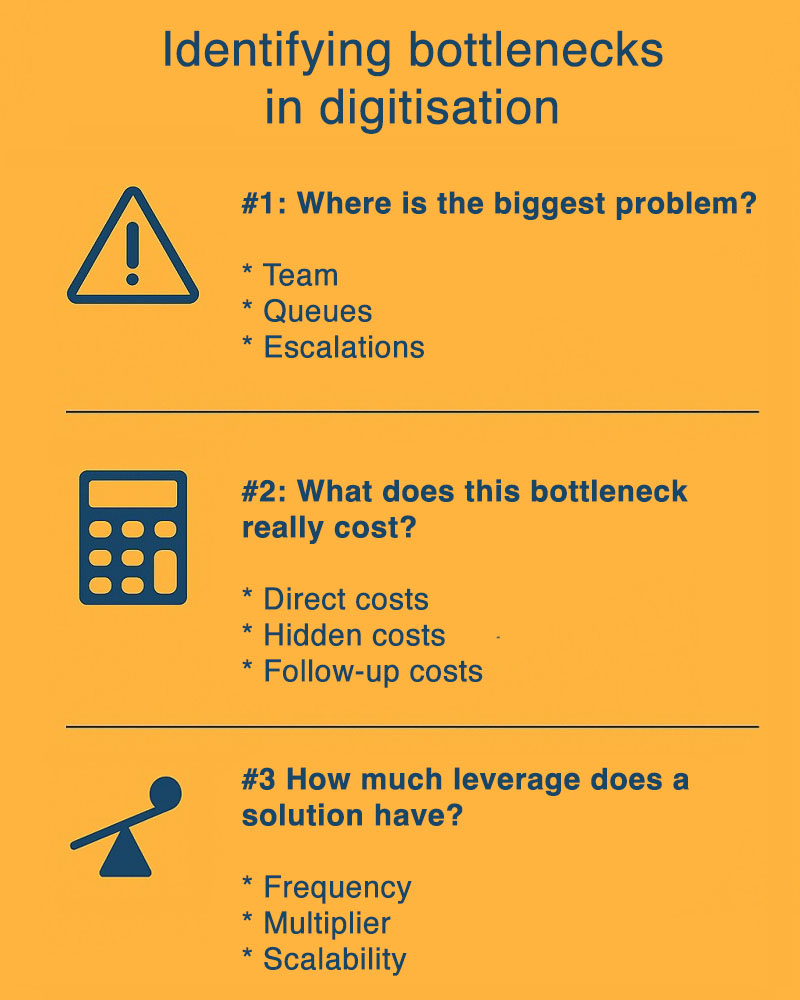

The three questions that reveal the bottleneck

Bottlenecks often operate in the background. They determine the pace, quality and workload of the company without being clearly identified. At the same time, almost every employee knows where the daily problems lie. This is exactly where the following three questions come in. They help you to clearly identify the bottleneck, understand its economic significance and realistically assess the potential of a solution.

Question 1: Where is the biggest problem?

The most important question is not what could be improved. It is: Where does it really hurt? A bottleneck is rarely difficult to find. It shows up where processes are left undone, where employees are regularly slowed down, and where customers noticeably wait.

You can find this point by combining three observations:

- Listen to your team. Ask openly which process takes the most time, where errors occur and where the workflow most often stalls. The answers are usually similar.

- Look at queues. Where do unfinished tasks accumulate? Where do backlogs, lists or downtime occur? Where are people, documents or data waiting to be processed further?

- Analyse escalations. Which processes lead to rework, coordination, delays or customer complaints? These patterns reliably show where the system is overloaded.

Bottlenecks are clear. Not three, not five. One. The one that takes up the most time, causes the most errors or generates the greatest dissatisfaction.

Question 2: What does this bottleneck really cost?

Many companies significantly underestimate the costs of a bottleneck. They only consider what is directly measurable, such as additional working hours, corrections or delays. However, the actual costs arise in the background. They lie in lost revenue, lost opportunities and the impact on motivation and staff turnover.

In practice, it is worth breaking down the costs into three groups:

- Direct costs. These include manual labour, correction loops, delay fees or complaints.

- Hidden costs. These arise when orders are not accepted, when teams perform routine work instead of adding value, or when good employees leave the company because processes are constantly frustrating.

- Follow-up costs. These manifest themselves in poorer customer experiences, longer delivery times or the loss of market opportunities.

When you add up these items, you can see the actual economic impact of the bottleneck. In many cases, it far exceeds the annual expenditure on digitalisation. This illustrates why the targeted elimination of a single bottleneck often has a greater impact than many parallel projects.

Question 3: How much leverage does a solution have?

Not every bottleneck has the same value. Some can be improved manually, while others are less relevant from a business perspective. The crucial question is therefore: What impact would a solution have and how much would it change the overall system?

Three factors are decisive:

- Frequency. The more frequently a process is run, the greater the impact of each optimisation. A time saving of just a few minutes can generate considerable leverage if the repetition rate is high.

- The multiplier. Some solutions not only reduce effort, but also improve subsequent processes, reduce error rates, increase capacity or enhance the customer experience. Such multiple effects determine how effective digitisation actually is.

- Scalability. A solution only reveals its full value when it can also cope with growing volumes. A bottleneck that is solved today must not reappear tomorrow.

Only when these three factors come together does a leverage effect arise that justifies digitalisation. Anything less than this is optimisation at the wrong level.

Figure 1: Identifying bottlenecks in digitisation

These three questions form the basis of any successful digitalisation strategy. They reveal which processes are actually slowing down your company, how high the costs are, and whether a solution justifies the expense. This is the starting point for focused digitalisation.

The five steps according to the theory of constraints

The theory of constraints describes a clear process for systematically identifying and eliminating bottlenecks. The so-called process of ongoing improvement consists of five consecutive steps that work the same way in every organisation, regardless of size or industry.

Step 1: Identify the bottleneck

The bottleneck is the point in the system that limits overall throughput. It determines the maximum performance a company can achieve. It is identified by observing the value stream and analysing queues, throughput times and escalations. The bottleneck is always the process that creates the most backlog and most severely limits overall performance.

Step 2: Exploit the bottleneck

Before additional resources or investments are deployed, the existing bottleneck must be exploited as effectively as possible. This means that the bottleneck operates with minimal interruptions, is given clear priority and is only used for activities that absolutely must be carried out at this point. The aim is to fully exploit the existing potential without making any structural changes.

Step 3: Subordinate all other processes to the bottleneck (subordinate)

All processes and decisions must be aligned in such a way that they support the bottleneck and do not burden it. Workloads, planning, handovers and priorities are aligned with the capacity of the bottleneck. Anything that could slow down the bottleneck is reduced or removed. This step ensures that the entire system is synchronised with the bottleneck.

Step 4: Elevate the bottleneck

Once the bottleneck is being used to its full potential and is supported by the organisation, structural expansion can follow. This can be achieved through additional capacity, new employees, organisational adjustments or technological solutions. Investment only takes place at this stage. The aim is to increase the performance of the bottleneck so that it is no longer the limiting factor.

Step 5: Return to the first step

Once the bottleneck has been eliminated, a new bottleneck will inevitably arise elsewhere in the system. This is not a problem, but rather the desired effect. The system has become more efficient, and the bottleneck position has shifted. Now the process begins again at step 1. The theory of constraints is not a one-off project, but a continuous cycle of improvement.

The steps are clear, logical and build on each other. However, even well-managed organisations lose momentum at this point. Not because the method is difficult, but because certain habits of thinking unnoticeably block the process. Three typical mistakes occur time and again. We will take a closer look at these next.

The three most common mistakes when dealing with bottlenecks

Even when the bottleneck is clearly identified and the process is known, many companies fall into patterns of behaviour that significantly weaken the effect of the theory of constraints. These patterns are not technical, but organisational. They arise from routines, from historically grown processes and from the desire to pursue several goals at the same time. Three mistakes occur particularly frequently and should be consciously avoided.

Mistake 1: Mistaking symptoms for causes

Often, the starting point is where the problem becomes visible, such as excessively long response times, missing leads or unreliable data flows. However, such symptoms are rarely the actual bottleneck. The cause is almost always one level deeper, in a process that strongly influences upstream or downstream work.

This leads to investments in the wrong place. More demand does not translate into higher sales if the quotation process is too slow. New automation remains ineffective if the critical manual step remains unchanged.

What helps: Investigate where delays occur, not where they are noticeable. Only the cause is the bottleneck, not the visible disruption.

Mistake 2: Addressing multiple bottlenecks at the same time

When different areas appear to be under strain, it is easy to get the impression that there are multiple bottlenecks. This often leads to attempts to address several issues at once. But bottlenecks are, by definition, unique. There is always only one critical point that limits the entire system.

Dealing with several supposed bottlenecks in parallel leads to a lack of focus, competing priorities and projects that are not completed.

What helps: Select the point that has the greatest impact on the overall system. Deal with this bottleneck completely before tackling the next one.

Mistake 3: Using old patterns

Once the first bottleneck has been eliminated, there is often a noticeable sense of relief. This is precisely when many companies revert to old decision-making logic, reactivate previous project lists and distribute their budget across many projects at the same time. This leads back to the scattergun approach and interrupts the continuous improvement process.

What helps: After each improvement, check which process is now the new bottleneck. Only when this has been clearly defined can the next round of improvements begin. Anything else will lead to fragmentation again.

Conclusion: Effective digitalisation begins with clarity

Digitalisation rarely fails due to technology, skills or a lack of willingness. It fails because energy is spread across too many projects. Impact is achieved when a company recognises the process that is slowing down everything else and consistently addresses this issue. The theory of constraints provides a clear framework for this.

It helps to select the one measure from many possible projects that has the greatest impact on the overall system.

Once the bottleneck has been identified, a new focus emerges. Decisions become easier, priorities clearer and investments more transparent. Instead of launching numerous initiatives at the same time, a continuous improvement process emerges that has a measurable effect and conserves resources. This is precisely where digitalisation unfolds its strategic value.

The crucial step is therefore not choosing a tool, but gaining clarity about where your company is truly limited. Once this bottleneck is addressed, progress will be evident in many areas at once. Growth does not come from more projects, but from concentrated impact.

Notes (some in German):

Do you want to identify and eliminate the bottleneck in your digitalisation projects? Then Merlin Mechler recommends a 30-day plan:

The 30-day plan: Your introduction to effective digitalisation

Week 1: Identification and evaluation

Day 1 – 2: Conduct a short workshop with the people who are familiar with the day-to-day processes. Ask the three key questions:

- Where are the biggest bottlenecks?

- What is the real cost?

- How big could the leverage be?

Day 3–4: Analyse the economic impact. Take direct, hidden and follow-up costs into account. The aim is to obtain a realistic picture of the actual burden.

Day 5: Make a decision. The bottleneck that has the greatest impact on the overall system becomes the top priority.

Week 2: Stabilise and utilise

Day 6 – 7: Make the best possible use of the existing bottleneck. Reduce interruptions, clarify priorities and create the conditions for the bottleneck to work continuously.

Day 8 – 10: Subordinate other processes to the bottleneck. Review workloads, interfaces and handovers. Anything that puts a strain on the bottleneck is adjusted or temporarily stopped.

Week 3: Find and evaluate solutions

Day 11 – 13: Analyse possible solutions. These could be organisational adjustments, additional capacity or digital tools. The key thing is that the solution has a direct impact on the bottleneck.

Day 14–15: Compare the options. Focus on a few approaches that can be implemented quickly. Choose the option that promises the greatest and fastest relief.

Week 4: Decision and implementation

Days 16–18: Make the decision and prepare for implementation. Responsibilities, timetable and expected effects are clearly defined.

Days 19–30: Start a pilot. Small, controlled and close to the actual process. Observe the effect. Optimise where necessary and confirm the result with figures.

After 30 days, you will not only have identified the bottleneck, but also set a concrete course of action. You will see the first effects, have clarified priorities and have a solid foundation for the next steps. This marks the beginning of the continuous improvement process that makes digitalisation tangible.

Do you require external support with the 30-day plan? Then simply contact Merlin Mechler on LinkedIn.

[1] McKinsey Transformation: Perspectives on transformation

[2] Bitkom-Studie 2025: Digitalisierung der Wirtschaft

[3] GPM: Theory of Constraints (TOC): Definition, Prinzipien & Anwendungsbereiche

Would you like to discuss bottlenecks in digitalisation and possible solutions as an influencer or opinion leader? Then share this post in your networks.

Merlin Mechler has published another post on the t2informatik Blog:

Merlin Mechler

Merlin Mechler is the founder of MidScale, an automation partner for small and medium-sized businesses. MidScale accelerates cash flow through AI-supported process automation and service agents that eliminate operational bottlenecks in customer service, back office and logistics – with go-live in 14 days and ROI from the first month.

Previously, he headed up sales at an IT company for senior developers and knows the economic effects of technical decisions from practical experience. His focus: efficiency through clarity, data and structure.

In the t2informatik Blog, we publish articles for people in organisations. For these people, we develop and modernise software. Pragmatic. ✔️ Personal. ✔️ Professional. ✔️ Click here to find out more.